Static & Grounding

Overview

CNC systems often include components or tools that can generate significant amounts of static electricity and/or transient voltage events.

Static Discharge

Static electricity is an imbalance of electrical charge on the surface of an object typically created when materials rub together.

In a dust collector or vacuum, this happens when dry air and fine dust particles are pulled at high speed through a hose. The constant friction between the moving particles and the inner walls of the hose strip electrons from the particles, causing significant charge to build up on the hose.

Plastic or vinyl hoses are particularly bad for generating static. Dust clinging to the hose or a small zap when touching the system is an indicator of static buildup.

Voltage Transients

Voltage transients, also known as surges or spikes are extremely short but intense bursts of high voltage that can disrupt or damage electrical equipment.

In a CNC environment, they are commonly generated by the switching of inductive loads such as motors.

Large motors such as vacuums or dust collectors create voltage transients when turned on or off due to the generation or collapse of magnetic fields. Some motors also use brushes which can also generate voltage transients due to sparking.

Variable frequency drives (VFDs) used for CNC spindles control motor speed by rapidly switching power. This switching is also a source of voltage transients.

The Importance of Grounding

Proper grounding is the single most important defense against both static electricity and voltage transients, but it combats each one in a slightly different way.

Think of a grounding system as a safe, low-resistance "drain" connected to the earth. The earth is so large that it can easily absorb or supply electrons without changing its overall electrical potential, making it the perfect "zero-volt" reference point.

How Grounding Combats Static Electricity

The Static Problem

Static electricity (from your dust collector, for example) is a slow, steady buildup of an electrical charge (excess electrons) on an insulated surface, like a plastic hose. This charge builds and builds until it has enough potential (voltage) to suddenly arc to a nearby object with a different potential — like your hand or another electronic component.

Static discharge or sparks can also create an electromagnetic pulse (EMP). As an analogy, think of the static discharge as slapping a pool of water. The slap sends out sharp, powerful ripples that travel in all directions. The EMP, like the ripples, is a "dirty" burst of broadband noise like a radio station playing thousands of songs at the same time. This broadband noise is disruptive to electronics and can even be picked up by circuit board traces or cables (which act like antennas) across the room.

Grounding for Static

Grounding provides a continuous path to the drain. By connecting a ground wire to all the conductive parts of your system (a practice called "bonding") and then connecting that entire bonded system to the earth (grounding), you give those excess electrons an easy escape route. Instead of building up to a dangerously high voltage, the static charge "leaks" away to the ground as fast as it's generated, keeping the entire machine at a safe, neutral potential.

How Grounding Combats Voltage Transients

The Voltage Transient Problem

A voltage transient (from a VFD or motor) is a sudden, high-energy burst of voltage. This "jolt" needs to go somewhere immediately. Without a ground path, it will try to find the path of least resistance, which is often through the delicate microchips in your CNC controller or VFD. This can lead to undefined behavior or damage.

Grounding for Voltage Transients

Grounding acts as a safety valve or "spillway" for this sudden surge. The ground wire provides a much easier path for that massive, unwanted voltage to travel than the sensitive electronics. The transient is safely diverted directly to the earth, bypassing and protecting your expensive components.

This is also why we use surge protectors, which are devices designed to quickly shunt transient voltages from the power lines directly to the ground pin.

Tips for Grounding CNC Systems

ELECTRICAL SAFETY

Solid Ground Connections

In North America, grounding rods or underground metal cold water pipes are often used for earth grounding. Consult your local building codes and regulations.

UNSAFE GROUNDING

Copper cold water pipes that travel underground can be a good candidate for earth grounding.

Ground clamps can be used to provide a solid earth connection to the pipe. Two screws secure the clamp to the pipe and a third screw acts as a terminal connection for the ground wire.

Dust Collectors

Dust collectors and/or vacuum systems are one of the primary sources of static electricity issues in a CNC system.

Bonding and grounding for dust collection is critical to prevent damage and ensure a safe and reliable setup.

- Metal Ducts: ensure that every component (pipes, elbows, blast gates) is electrically connected to the next component. This is known as bonding. Once the entire system is bonded, it should be connected to a proper earth ground.

- Flexible Hose: Most plastic flex hoses have a bare metal wire running through them. This wire must be grounded. It should also be bonded to the chassis of the dust collector (which itself should be grounded) and to the metal body of the spindle on the CNC machine.

Dust Collection Materials

Whenever possible, use static-dissipative hoses or metal ductwork instead of PVC or plastic pipes, which are excellent insulators and can make static problems worse.

CNC Chassis and Axes

A CNC machine can be "noisy" from an electrical point of view. The environment in and around the machine can create several issues:

- Voltage Transients: from motors and VFD spindles

- Static Discharge (ESD): from the dust collector or gantry (axis) movement

- Electromagnetic Interference (EMI): from the spindle motor and high-power wiring

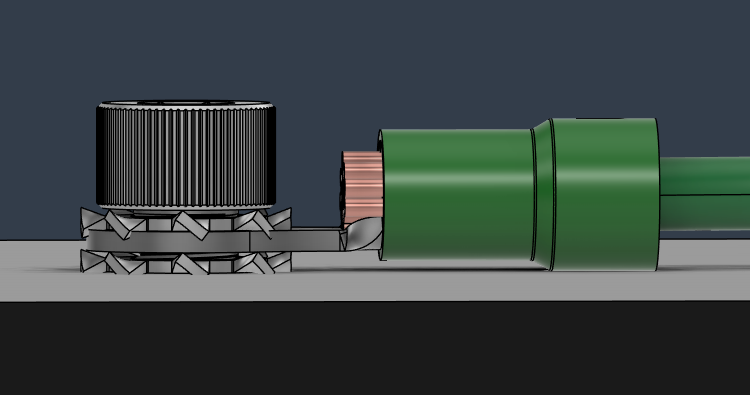

It is important to ensure a solid and reliable connection when bonding the chassis of the CNC to ground. Once reliable way to accomplish this is to use external tool (or "star") washers.

A grounding stud with nuts or screw is used to compress the washers and "bite" into the metal of the chassis and the ring terminal on the ground wire.

VFD & Spindles

Spindles and their VFD drives can be a significant source of electrical noise.

- The VFD and spindle body should be properly grounded.

- Some inexpensive VFDs are sold without proper safety and elecromagnetic compliance certifications. Look for certifications marks and documentation.

- Always use properly rated and shielded cable between the VFD and the spindle.

Certifications

Examples of safety certifications are CSA (Canada), UL (U.S.), TUV (Global), and CE (Europe).

Electromagnetic Compatibility (EMC) certifications include CE (Europe), FCC (U.S.) and Industry Canada (IC).

Consult your local regulations for more info.